Air Systems

Air Curtains

Industrial and commercial high velocity air curtains

Non-heated and electrically / hot water / steam / gas heated aircurtains

Environmental air barriers

Wind stop air curtains

Insects stop aircurtainss

Above door and side mounting options

Dust Collection Fan Systems

Cyclone and cartridge type dust collctors

Fume extractor fans

Air Scrubbers

Local fume exhaust ventilator systems

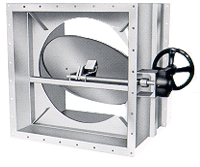

Dampers and Actuators

Fan and blower air dampers

Isolation / flow diverter dampers

Louvers and shutters

Air Systems

High penetration blow-off air-knives and blower air-cannons

Air curtains / gas gates / air screen fans

Material handling & pnematic conveying blower systems

Silencers and Fan Enclosures

Blower and fan silencers

Metal & FRP ventilation systems

Vibration eliminators and acoustial blower enclosures

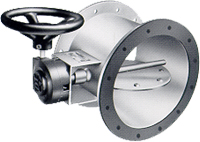

HVAC Controls

Electric & pnematic fan damper actuators

Motorized Blower Valves

Fan VFDs